Precision and clarity are paramount in the dynamic landscape of modern industries. Professionals across various fields rely on advanced tools to maintain high standards and achieve unparalleled accuracy. The Dino-Lite digital microscope has emerged as a versatile and indispensable device among these tools. Renowned for its portability, user-friendliness, and exceptional imaging capabilities, the Dino-Lite microscope has found applications in numerous sectors, including forensics, manufacturing, electronics, and quality control.

Forensics: Unveiling the Truth with Clarity

The Dino-Lite microscope is an essential tool in forensics, where every detail can be the difference between justice and injustice. Forensic scientists use these microscopes to meticulously examine evidence such as hair fibres, skin cells, and fabric threads. The high magnification and superior imaging quality of the Dino-Lite allow for the detailed analysis of minute samples that are often crucial in criminal investigations.

One notable application is in the analysis of counterfeit documents. Forensic document examiners employ Dino-Lite microscopes to scrutinise the fine details of suspected forgeries. The microscope’s ability to capture high-resolution images aids in identifying inconsistencies in ink patterns, paper fibres, and printing techniques. This meticulous examination is instrumental in verifying the authenticity of documents and can be pivotal in legal proceedings.

Additionally, Dino-Lite microscopes are utilised in crime scene investigations. Investigators can use these portable devices to examine trace evidence on-site, providing immediate insights without transporting samples to a lab. This capability not only speeds up investigations but also preserves the integrity of the evidence, ensuring that crucial details are not lost or contaminated during transit.

Manufacturing: Ensuring Precision and Quality

In the manufacturing sector, precision is synonymous with quality. Dino-Lite microscopes are crucial in ensuring that products meet stringent quality standards. From automotive components to medical devices, manufacturers use these microscopes to inspect parts for defects, measure dimensions, and verify compliance with specifications.

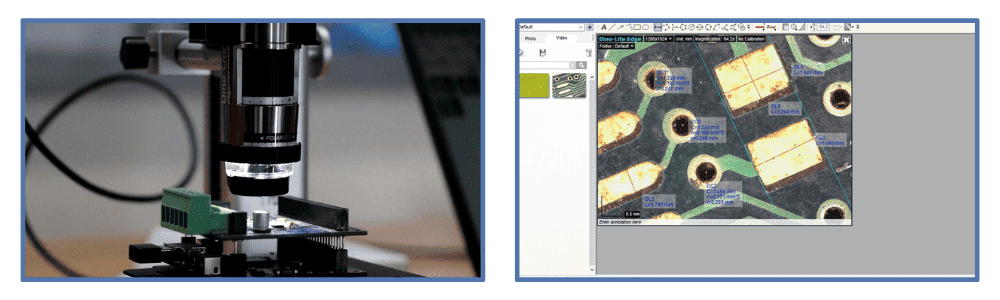

For instance, even the slightest imperfection can lead to significant malfunctions in electronic component production. Dino-Lite microscopes enable manufacturers to inspect solder joints, circuit boards, and microchips with exceptional clarity. The high magnification allows the detection of invisible defects to the naked eye, ensuring that only flawless components move forward in the production process.

Furthermore, Dino-Lite microscopes are invaluable in the quality control of precision-machined parts. Engineers and technicians use these devices to measure surface roughness, check for microscopic cracks, and ensure that parts adhere to exact specifications. The ability to capture detailed images and perform measurements directly on-screen enhances efficiency and accuracy in quality control processes.

Electronics: Enhancing Detail and Reliability

The electronics industry, characterised by rapid innovation and miniaturisation, demands tools to keep pace with its evolving needs. Dino-Lite microscopes have become indispensable in this field, allowing engineers and technicians to examine and troubleshoot complex electronic assemblies.

In PCB (printed circuit board) inspection, Dino-Lite microscopes identify manufacturing defects, such as solder bridges, component misalignments, and damaged traces. The microscopes’ high-resolution imaging and adjustable lighting options allow for a thorough examination of intricate PCB layouts. This detailed inspection is crucial for ensuring the reliability and performance of electronic devices.

Moreover, Dino-Lite microscopes are used to repair and rework electronic components. Technicians rely on these devices to inspect and repair small-scale components, such as microchips and connectors. The microscopes’ precision and versatility enable technicians to confidently perform delicate tasks, reducing the risk of further damage and improving the success rate of repairs.

Quality Control: Maintaining Standards Across Industries

Quality control is a critical aspect of any industry, and Dino-Lite microscopes have proven to be valuable assets in maintaining high standards. These microscopes are used in various quality control applications, from inspecting raw materials to verifying finished products.

For example, Dino-Lite microscopes are used in the pharmaceutical industry to inspect drug formulations and packaging materials. The microscopes’ ability to provide clear, magnified images aids in detecting contaminants, ensuring that products are safe for consumption. Additionally, in the food and beverage industry, Dino-Lite microscopes are used to examine food samples for foreign particles and quality issues, helping to uphold safety and quality standards.

Another significant application of Dino-Lite microscopes is in inspecting textiles and garments. Manufacturers use these devices to check for defects in fabric, such as weaving errors and surface irregularities. Dino-Lite microscopes’ high magnification and imaging capabilities enable detailed inspection, ensuring that only high-quality textiles reach consumers.

Conclusion: A Tool for Precision and Excellence

The Dino-Lite microscope has become a versatile and essential tool across various industries. Its forensics, manufacturing, electronics, and quality control applications underscore its importance in modern professional practices. Dino-Lite microscopes empower professionals to achieve excellence in their respective fields by providing unparalleled clarity and precision. As industries evolve and demand higher standards, the Dino-Lite microscope will remain a cornerstone of accuracy and quality assurance.

In forensics, the ability to scrutinise evidence with unmatched detail aids in the pursuit of justice. In manufacturing, ensuring precision and quality translates to superior products. The electronics industry benefits from the microscope’s capability to enhance the reliability of intricate assemblies, while quality control across various sectors is elevated by its detailed inspection capabilities. The Dino-Lite microscope exemplifies how advanced technology can revolutionise practices, improve outcomes, and set new benchmarks for excellence in professional fields.

As technology advances, the potential applications of Dino-Lite microscopes are bound to expand further. Their role in enhancing precision, efficiency, and quality across industries highlights the transformative impact of innovative tools in the hands of skilled professionals. The Dino-Lite microscope is not just a tool; it is a testament to the power of technology in driving progress and achieving unparalleled standards of excellence.